Honouring the team that developed the Bailey Bridge in the Second World War

and live on Freeview channel 276

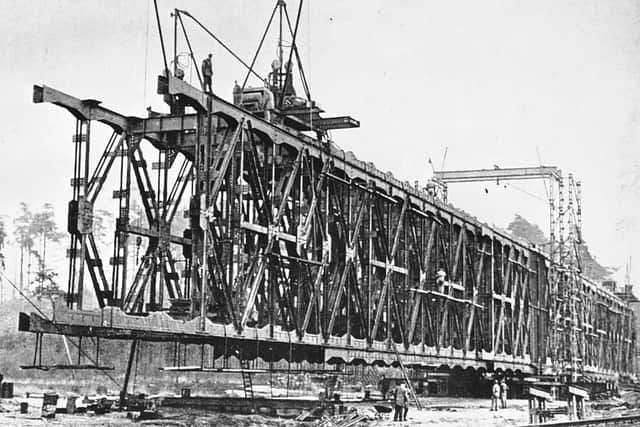

Bailey bridges are portable and pre-fabricated, developed by the British in 1940-41 for military use during the war, as they needed no special tools or heavy equipment to assemble.

Michael Cleary, 85, of Salters Lane, is keen to honour the bridge design team, based at the Military Engineering Experimental Establishment (MEXE) in Christchurch, men and women who made an immense contribution to the Allies’ victory.

Advertisement

Hide AdAdvertisement

Hide AdHe said: “My father Thomas was well known in Hastings. He awarded contracts to several engineering companies involved with the World War Two bridging and pumps procurement and manufacture.

“My father was only 32 and although he had been advanced by the Royal Engineers in his education and electrical and mechanical engineering, he was still regarded as ‘the boy’ among senior engineers.

“He soon became a man of importance and activity, dynamic is the word. The success was transferred to full production at Braithwaites, West Bromwich, and component manufacture by so many firms in the Midlands.

“Let us not forget the lady welders. Without this skill, the 400km of bridging would never have happened. Training, co-ordination, material supplies, tool making, transport, the story goes on and on. Very little has been recorded of these times.”

Advertisement

Hide AdAdvertisement

Hide AdThomas Cleary was taken on by the Royal Engineers after his father was killed on Armistice Day, at the end of the First World War, along with all his bridging troop.

Michael said: “The Royal Engineers took kindly upon his mother’s pressure and he was seen to be a bright guy. His work on pumps, machine tolerances and so on prompted his appointment.

“My father was enlisted and educated by the Royal Engineers. He then was to become a skilled mechanical engineer. As a result, he was placed in the Bailey bridge team, with his devotion to tolerances and metallurgy. He was subordinate to ‘a great bunch of engineers’, in his words.

“The bridging team was led by Major Charles Edward James Jarrett-Kerr, who was awarded a CBE exactly 80 years ago. They responded to the demands of Major Ralph Freeman to design a bridge.

Advertisement

Hide AdAdvertisement

Hide Ad“Sir Donald Bailey had been instructed to improve upon previous truss bridge concepts, such as the Callender-Hamilton and the Martell. The need was for a bridge that could carry 40 tons and be speedy in construction without the use of mechanical equipment, that is, just military personnel. A longer span, of course, was pushed to a landing via the rollers on to the abutment with a tracked dozer.

“The bridge was accredited to Bailey. Previous bridges, heavy in sectional steel, experienced a ‘wobble’ due to the truss-connecting pins being loose, hence limiting the load capacity.

“The team reduced the bridge panels in size to just ten feet and light enough for a six-man carry. Next the pin. This was critical. The pin and socket designed was made from a steel alloy containing manganese and molybdenum with a high shear strength. The socket and pin merely 209.55 x 47.625 millimetre diameter was made to a close tolerance with almost a polished surfaces.

“Under stress, with machine guns and bombs ‘intruding’, our soldiers had to cope with mud, filthy water and ice, which required much strength and endeavour to get the pins home and secure. Many a sergeant could be heard bellowing ‘Get it in!’.”

Advertisement

Hide AdAdvertisement

Hide AdMichael has had the names of the team confirmed by Think Defence and says: “So it is with pride that the families of the following will perhaps in turn recall stories told by their grandparents, too - H.J. Taylor, R.S. Lane, A.T. Bines, B.M. Furneaux, S. Mountney, Brig F.E. Fowle who was later awarded the MC, Colonel S.A. Stewart, Colonel P.K. Benner, Colonel S.G. Galvin and Major H. W. Kenyon.

His father, at the age of 34, was assigned to Braithwaite & Co in West Bromwich and Michael vaguely remembers the family being moved to Birmingham, where they lived until 1946.

Michael said: “Material supply, tools, jigs, welding and testing were all part of the intensity over a short period. Many other firms were ordered to supply components, completing the bridge sets. The logistics of ordering, delivery and shipping were an immense task which can only be imagined now but was a real and fantastic effort by so many. We must all be truly thankful.

“The vast quantity of bridging and the components that were manufactured enabled more than 400km to be sent into Europe, not only to advance and win the war but post-war during the extensive reconstruction of Germany.

Advertisement

Hide AdAdvertisement

Hide Ad“The stories of the Bailey bridge and the harrowing experiences of the soldiers who survived, and of those who bravely died in order to build these large bridges and pontoon bridges, has been written up by so many involved.”